Premier Medical System Company is specialized in “Medical

Gas System”, “Medical Air” , “Vacuum Systems”, “Manifolds”,

“Monitoring equipment” and “Pipeline components” and “Gas

Outlets” & “Bed Head Units” & “Safety Test Tubes” Surgical Lights & Hospital Furniture,. We

assist our customers with exceptional technical support and customer service to

maintain our name as one of the largest Medical Gas service providers in Meddle

east regions.

We

offer complete solution for the Medical Gas System of hospitals. All the system

consists of “Medical Gas Generators”, “Manifolds”, “Pipeline

system”, “Area Control Units”, “Alarm Systems”, “Monitoring

Screens” and the final “Gas Outlets” & “Bed Head Units”

in Operation Theatres, and We aim to be the global innovation leader in “Medical

Gas System”, “Medical devices” and “Medical Consumable products”

& “Bed Head Units” & “Safety Test Tubes”, Surgical Lights & Hospital Furniture, we intend to

grow the value of our business by developing safe and effective products to

meet Health Care sectors needs and improve patient care.

Vision

We aspire to be the preferred

and distinguished partner for medical care providers in the Kingdom

of Saudi Arabia and to participate in creating a new future of distinguished medical projects to serve and interest

the patient.

Mission

We aim to be the global innovation leader in Medical Gas System ,medical devices and Medical Consumable products. We intend to grow the value of our business by developing safe and effective products to meet Health Care sectors needs and improve patient care.

BED HEAD UNIT

Our philosophy is a commitment to the different needs of the involved groups: • Bringing the latest and practical technology to doctors and nurses enabling them easy access to all services.

• Integrating the outfit of the bed head unit to the architectural character of the hospital to give the patient the most relaxed atmosphere as possible under the circumstances.

• Easy and well-designed installation features, help the installer and service team to save costs during installation and ensure a long life-cycle with low maintenance efforts and costs.

|

GAS

DISTRIBUTION EFFECTIVE PIPING AT SITE, PARTITIONED FROM MAIN AND LOW VOLTAGE

SUPPLY

|

LIGHTING

Different

rooms lights integrated in the units or as external equipment

|

MOUNTING RAIL

To be used

along the whole unit or partial along the power supply section

|

BED HEAD UNIT

This catalogue gives overview for the technical details of following product ranges:

•Ward Unit H250: horizontal bed head units for Normal care bedrooms, Intensive Care areas and Dialysis stations

•Ward Unit V500: vertical headwall or flatwall concept for Normal Care bedrooms integrating with living room needs in private clinics

•Duke: High-end solutions as a mixed state of the art technology, individual design and workmanship with finest materials

•Kindergarten: To make the little ones enjoy a warm atmosphere and feel at home with a full technical bed head unit

•Light fittings LF 150: Complete lighting concept for application in health care areas and elderly homes

•Picasso 500: Covered Bed head units, only visible when required

Product & Services: CPX degreased copper tube

Product Description:

CPX degreased copper tube and fittings are manufactured in the UK under BS EN

13485 Medical Devices: Quality Management Systems. CPX copper tube is the only British

manufactured tube that is CE marked as a Medical

Device 93/42/EEC under CE0086.

CPX degreased copper

tube is manufactured from phosphorous deoxidized (non- arsenical) copper alloy CW024A. The chemical composition being CU.DHP to ISO 1190- 1/CW024A to EN1412. The raw material

is a combination of cathode

(electrolytically pure to 99.9%) and proportion of controlled reworked material. The mechanical properties of CPX degreased copper tube is in accordance with BS EN 13348

•

R250 (half hard) for sizes up to 54mm in diameter

•

R290 (hard) for sizes 67mm + in diameter

Precision UK’s CPX degreased copper tube is manufactured in the UK under BS EN 13485 Medical Devices: Quality Management Systems. All tube is manufactured under strict quality control procedures to ISO 9001:2008. CPX tube is the only British manufactured tube that is CE marked as a

class IIa Medical Device 93/42/EEC with notified body British Standards Institute under CE0086.

It is suitable for jointing degreased medical gas copper fittings and other medical gas equipment compliant to BS EN 13348, BS EN 1057, BS 2871 Part 1 Table X, EN 7396 and

HTM 02-01. CPX copper tube is designed for use in Medical Gas Pipeline System (MGPS) installations and incorporates the specialist requirement of the MGPS industry to include cleanliness, packaging and usability required to attain the levels of quality as stated particularly in HTM 02-01.

Specific Benefits Include:

•Each pipe is cleaned to have a maximum carbon level 0.20mg/dm².

•Each pipe is individually end capped and bundled in sealed polythene bags to maintain cleanliness.

•Chemical composition CU.DHP to ISO 1190-1/CW024A to EN1412.

•All copper tube is manufactured under strict quality control procedures to ISO 9001: 2008 and CE marked under the Medical Device Directive 93/42/EEC (CE0086).

•BSI Kitemarked

•Batch numbering for traceability is included on all pipework.

•All copper tube from sizes 12mm through to 108mm

are engraved/permanently ink marked with the following information: EN 13348, nominal dimensions, manufacturer

details, part no., CE Mark, , Medical Device Directive to 93/42/EEC, time and date of production.

•25 year guarantee.

The CPX lockable line valve is manufactured in the UK under BS EN 13485 Medical Devices: Quality Management Systems and CE marked with notified body British Standards Institute under the Medical Device Directive 93/42/EEC (CE0086). They are designed to have a tight shut off and blow out proof stem for protection against pressure surges. They comprise of a 2-piece full bore male threaded nickel plated brass ball valve c/w chrome plated brass ball, blow- out proof stem, stem O-ring, Teflon® ball seals and flat face copper stub pipe assemblies. The copper stub pipe assemblies are manufactured from medical gas copper tube

compliant to BS EN 13348 and are factory soldered to brass flat face seal housings chemically cleaned and degreased.

The copper pipe stubs are of sufficient length to enable brazing directly to the MPGS utilizing flux less brazing to

WKO (82) 1. Flat face housing incorporate Nitrile® or Viton® O- ring seals ensuring 100% gas tight connections.

The chrome plated valve handle is lockable in the open or closed position by way of a sliding device and a brass

padlock is provided to prevent unauthorized or inadvertent

operation of the valve. For ease of installation all brass padlocks are the same size for the full range of ball valves from 15mm to 108mm.

All line valves are fully pressure tested for valve tightness and leakage and batch numbered for traceability prior to packing and delivery. They are individually end capped and sealed in a clear polythene bag to maintain cleanliness.

Designed to meet the requirements of

•HTM 02-01: Health Technical Memorandum Medical Gas Pipeline Systems.

•C11 NHS: Model Engineering Specification – Medical Gases.

•BS EN 7396: Pipelines for Compressed Medical Gases and Vacuum.

•BS EN 15908 Non-interchangeable Screw Threaded (NIST) Low Pressure Connectors for Medical Gases.

•Medical Device Directive 93/42/EEC (CE0086).

Suitable for use with the following medical laboratory gases

O2

N

2O (Nitrogen)

O 2/N2O

Medical Air Vacuum CO

2

Helium

Hydrogen Argon

Mixtures of the above

The CPX Terminal Units are designed and manufactured in the UK under BS EN 13485 Medical Devices: Quality Management Systems. The units comprise of a first fix, second fix and a second fix valve assembly and connect medical appliances to the gas supply system.

The first fix comprises of a brass pipeline termination cylinder with a 12mm BS EN 13348 copper pipe for brazing to the fixed pipeline system, or with a NIST BS EN 15908 (non- interchangeable screw thread) connector for connection to a hose assembly. A mounting box suitable for both surface and flush installations is also provided.

The CPX Terminal Unit is designed to enable gas probes

to be connected and disconnected easily and with minimal effort and the same time as giving a strong, reliable and secure connection. They are available for oxygen, nitrous oxide, 50% oxygen/50% nitrous oxide mixture, medical air, surgical air, medical vacuum, carbon dioxide, nitrogen and AGSS.

The terminal units can be flexibly integrated into any type of installation including surface, flush, bedhead and pendant and are supplied with a 3 year warranty. Test plugs are included with flush, surface, and bedhead types for first fix pressure testing on site.

Standards

Designed to meet the requirements of (but not exclusive to):

•HTM 02-01 Medical gas Pipeline Systems

•BS EN 7396-1 Pipelines for Compressed medical Gases and Vacuum

•BS EN 7396-2 Anaesthetic Gas Scavenging Disposal Systems

•BS EN 9170-1 Terminal Units for use with Compressed Medical Gases and Vacuum

•BS EN 9170-2 Terminal Units for Anaesthetic Gas Scavenging Systems

•C11 NHS Model Engineering Specification – Medical Gases

•BS EN 15908 Non-interchangeable Screw Threaded (NIST) Low-pressure Connectors for Medical Gases

•BS 5682 Specification for Probes Specification for Probes (quick connectors) for Medical Gases.

•Medical Device Directive 93/42/EEC (CE0086).

AVSU - Area Valve Service

Unit

The Area Valve Service Units (AVSU’s) are manufactured under BS EN 13485 Medical Devices: Quality Management Systems and Medical Device Directive 93/42/EEC (CE0086). They provide a local gas isolation facility for use during normal installation and maintenance or in the event of an emergency. They are built in accordance with the HTM02-01, C11 and

BS EN 15908 standards and are suitable for Oxygen, Nitrous Oxide, Oxy-Nitrous Oxide, MA4, MA7 and Vacuum.Features:

The AVSU can be installed as a flush or surface mounted. •

Housed in a steel white epoxy coated box and a key operated 90° lock for security.

•Abreakable glass front to the door gives an immediate indication as to the gas type, the valve position and the gas flow. In an emergency the glass front can be broken

thus allowing access to the valve.

•The valve type is a 90° shut off ball valve, which is operated via a handle, and each unit comes complete with a blanking plate, which can be fitted, to either side

of the valve.

•Each NIST include non-return valves with 100% sealing.

•Non-interchangeable NIST connectors are fitted upstream and downstream of the valve. The NIST connectors provide the facility to purge a system

before the working gas is introduced and also following any downstream interruption of the supply. The NIST connectors also allow for the pipeline pressure to be tested and provide an easily accessible point for gas sampling.

•Side entry sizes available 22mm, 28mm and 42mm (other entry versions available).

•Pressure switches if required can be fitted inside the box to enable local monitoring.

Area Alarm Unit

The CPX-A area alarm is used to monitor pipeline pressure within a ward, theatre etc. The pressure is monitored by pressure switches in the pipeline downstream from the last AVSU. Pressure is monitored for both high and low pressure (low only for vacuum). The integrity of the cabling between the pressure switches and the alarm panel is monitored, and

a fault on this cable will result in a system fault alarm, with all affected alarm conditions going into alarm condition.

Simple connection: Just 3 cores connect the alarm to the end of line components, regardless of the number of gases. Simple maintenance: All connections (including mains) are plug & socket. The alarm components can be changed in about 1.5 minutes.

Versatile: Several CPX-A alarms can be connected to the same end of line components using just 3 cores. The CPX-A can transmit either a common alarm or all alarm conditions, using the MEDCON data protocol, for display on the CPX-P plant alarm system, and can also receive data from the

CPX-P system.

2 year warranty: No parts or labour charges for repairs to alarms which fail due to faulty parts or manufacture.

10 year compatibility warranty: Install the CPX-A with the confidence that equipment will be available to modify or extend the system for at least 10 years.

All alarms are manufactured under BS EN 13485 Medical Devices: Quality Management Systems and comply to HTM02-01, BS EN 7396 and BS EN 4754.

The monitoring of the cable requires a termination box to be mounted as close as practical to the pressure switches. As an optional extra, these termination boxes can be supplied with the cables for connection to the pressure switches already fitted, allowing significant savings in on-site work.

To use more than one CPX-A alarm panel with one set of pressure switches, simply connect all CPX-A alarm panels to the 3 core screened cable (minimum 0.5mm) from the termination box (either at the termination box itself, or at

another CPX-A).

Medical

Vacuum Plant - British Standard

Precision UK’s CPX Vacuum Plant is manufactured under BS EN 13485 Medical Devices: Quality Management Systems.

It provides a centralized source of vacuum, available in simplex to multi-pump configurations dependent on individual requirement, to include complete package plant or modular format.

Specific Benefits Include:

•Fully complies to HTM 02-01, HTM 2022, C11, BS EN 7396

•CPX® branded solid British design

•Control and highly visible indication panel

•All interconnecting pipework is included

•Outlet pipework for connecting to the pipeline

•Anti-vibration mounts on all pumps

•Isolator to each pump unit as standard

•Alarm and BMS outputs for remote status indication

•Digital display available on request

•All settings are factory set and verified with certificates of inspection

•Each plant has a full warranty of 12 months from its commission date.

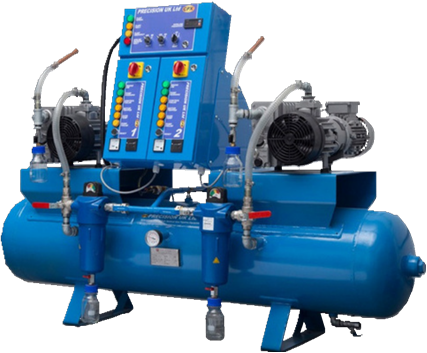

Medical

Air Plant - British Standard

Precision UK’s CPX Medical Air Plant is manufactured under BS EN 13485 Medical Devices: Quality Management Systems. It provides a centralized source of medical air,

available in simplex to multi-pump configurations dependent on individual requirement.

Specific Benefits Include

•Fully complies to HTM 02-01, HTM 2022, C11, BS EN 7396

•CPX® branded solid British design

•Control and highly visible indication panel

•All interconnecting pipework is included

•Outlet pipework for connecting to the pipeline

•Anti-vibration mounts on all pumps

•Isolator to each pump unit as standard

•Alarm and BMS outputs for remote status indication

•Digital display available on request

•400Kpa, 700Kpa and 1000Kpa output versions available

•All settings are factory set and verified with certificates of inspection

•Each plant has a full warranty of 12 months from its commission date

AGSS Plant - British Standard

Precision UK’s CPX AGSS Plant is manufactured under BS EN 13485 Medical Devices: Quality Management Systems.

It provides a centralised or dedicated source for the safe removal of exhaled anaesthetic gases from within the

theatre, available in simplex and duplex pump configurations dependant on individual requirement.

Service and Maintenance

Throughout the UK and worldwide our approved team of service and maintenance engineers provide immediate technical support.

Specific Benefits Include:

•CPX® branded solid British design

•Control and highly visible indication panel

•All interconnecting pipework is included

•Copper stubbed outlet and inlet pipework for ease of connecting to MGPS

•Anti-vibration mounts on all pumps

•Isolator to each pump unit as standard

•Alarm and BMS outputs for remote status indication

•Pre-set vacuum relief valve and low pressure sensors

•Low voltage (24V) remote switches

•Visible condensate drain flask fitted to exhaust

•Easy to install 4 wire + earth remote switch wiring

•All settings are factory set and verified with certificates of inspection

•Each plant has a full warranty of 12 months from its commission date

Designed to meet the requirements of

•HTM 02-01: Medical Gas Pipeline Systems

•C11 NHS: Model Engineering Specification – Medical Gases

•BS EN 6834: Specification for Active Anaesthetic Gas Scavenging Systems

•ISO 7396-2: Anaesthetic Gas Scavenging Disposal Systems.

Medical Gas Manifolds - British Standard

Precision UK’s CPX Automatic Manifold Plant is manufactured under BS EN 13485 Medical Devices: Quality Management Systems.

It provides a centralised source of bottled gas. The unit is designed to provide a duty and standby gas supply at a constant pressure via two banks of bottled gas cylinders with status monitoring.

•Astandard system would feature a central control panel with a header assembly.

•Digital display of bottle pressure for duty and standby banks.

•Electronic control with alarm and BMS outputs for remote status indication.

•The unit is designed for wall mounting as standard, however, options available include floor mounted assemblies and formats to suit customer requirements.

•Also available is a high flow capable of providing a distribution flow rate in excess of 2000 L/m.

Designed to meet the requirements of:

•HTM 02-01: Medical Gas Pipeline Systems

•BS EN 7396: Pipeline Systems for Compressed Medical Gases and Vacuum

•C11 NHS: Model Engineering Specification – Medical Gases

•BS EN 2503: Pressure Regulators

Service and Maintenance

Throughout the UK and worldwide our approved team of service and maintenance engineers provide immediate technical support.

Medical

Pendants - Multi Movement

The many advantages in the field of safety and hygiene are;

No more trailing leads or hoses to restrict movement within the department, all equipment is attached via short connecting hoses or cables to integral hook-up points.

The fully encapsulated system, incorporates modular service boxes, to ensure the maintenance and general use are unproblematic.

Single or two-piece and arm assemblies, motorized or static, the equipment can now be located at the point of use with simplicity.

Fully equipped as desired, with high and low

voltage supplies, medical gas outlet points, communication points, and miscellaneous.

Factory tested supplied to the customer in modular format

The Precision UK Pendant is a modular unit, which can be supplied with or without height adjustment. The pendant consists of a ceiling mount, upon which a wide selection of arms can be mounted.

For more information on specifications, contact the PMS team directly.

Medical Pendant – Multi Movement

Precision UK supplies a comprehensive range of high-quality ceiling suspension systems that have been developed under the

following criteria: Increased Safety, Increased Hygiene and Sterility Ease of use.

Standing Lifter – safe and simple to operate

The GLS5.2 Active lifter is a mobile standing lifter designed to facilitate day-to-day routines for users and carers alike. The GLS5.2 model is designed to lift the user from a seated to a standing position and is also useful for frequent everyday moves back and forth between bed, chair and bathroom. This active lifter thus provides a safe, simple and comfortable way to lift and support users with some or full control of their upper body.

GL5.2 Mobile lifters

Handle most lifting and moving needs

Options for both high and low lifts – even for large users User-friendly – simple to operate

Floor Lifters – comfort and safety

GL5.2 Mobile lifters constitute a floor-based alternative to ceiling-mounted lifting and moving systems.

Two versions of the GL5.2 model are available with lifting capacities of 155 kg/340 lbs and 205 kg/450 lbs, respectively. Both versions feature an automatic lifting and electric width setting. The GL5.2 has a maximum lifting height of 70 inches, which makes it possible to lift a person directly from the floor.

Company Projects

Because, we're here to help Kindly feel free to contact PMS with any questions.

Contact No.: 0507767386

Email: syed.h@med-premier.com

ADDRESS: Al Falah Building P.O. Box 6685,

Riyadh 13314, Kingdom of Saudi Arabia

Thank You

Comments